High-Performance DC Circuit Breaker - The NQCM1Z-H series offers reliable DC circuit protection up to 800V with 25kA breaking capacity. Ideal for photovoltaic systems, battery storage, and EV charging stations with non-polarized bidirectional current flow (charging/discharging) and fast short-circuit protection (<0.1s).

Durable & Safe Design - Features silver contacts for enhanced conductivity, flame-retardant materials that resist high temperatures, and custom arc magnets for efficient arc extinguishing. Mechanical life exceeds 8000 operations while electrical durability reaches 4500 cycles.

Versatile Applications - Perfect for solar PV systems (up to 1000V), battery banks (bidirectional protection), and EV charging piles. Compact size (165x75x104mm for 250A model) allows easy integration into various DC power systems.

User-Friendly Operation - Includes multiple operation modes (top/bottom terminals), manual trip button, and clear ON/OFF handle. Optional shunt trip release available for remote control. Meets IEC6047-2 standards with +40°C Cat A rating.

Optimized Connectivity - SC-type terminals support cables up to 70mm² (2/0 AWG) with 8mm hole crimped connections. Features overload protection, short-circuit protection, and voltage-current collection in one robust package.

PRODUCT INTRODUCTION

NQCM1Z-H series DC molded case circuit breaker (referred to as MCCB) are designed for DC and AC power system applications. They are rated for a working voltage of DC600V (36-600V) and a working current up to 1000A. The MCCB features a non-polarized design, supports bidirectional current flow and protection. It has overload and short-circuit protection functions, which can protect lines and power supply equipment from damage.

The products are widely used in new energy power (photovoltaics, generators, wind energy, batteries, etc.), electric vehicles, ships, industrial control, power supplies, telecommunications, rail transport, construction, and other industries.

This MCCB complies with the IEC60947-2 standard.

PARAMETERS

Product Model | NQCM1Z-125H | NQCM1Z-250H | NQCM1Z-400H | NQCM1Z-630H |

Electrical Characteristics | ||||

Pole Number | Non-polar 2P | |||

Rated Current Ie (A) (Support Customization of Other Currents) | 63, 80, 100, 125 | 160, 200, 250 | 300, 350, 400 | 500, 630 |

Rated Voltage Ue (V) DC | 600 (36-600) | |||

Rated Insulation Voltage Ui (V) DC | 1200 | |||

Rated Withstand Impulse Voltage Uimp (kV) | 8 | |||

Rated Circuit-breaker Breaking Capacity Icu (kA) | 25 | |||

Trip Type | Thermomagnetic Trip | |||

Trip Curve | 8In - 12In | |||

Short-circuit Protection Trip Time | <0.1s | |||

Pollution Degree | 2 | |||

Protection Functions | Overload Protection, Short Circuit Protection | |||

Isolation Function | Available | |||

Mechanical Characteristics | ||||

Mechanical Service Life (Times) | 8000 | |||

Electrical Service Life (Times) | 4500 | |||

Reference Ambient Temperature | 30°C | |||

Operating Ambient Temperature | -35°C - +70°C | |||

Storage Temperature | -40°C - +85°C | |||

Installation Characteristics | ||||

Terminal | Press Plate Type | |||

Maximum Torque | 13N.m | |||

Installation | Screws Fixed | |||

Optional Accessory | MX (shunt release), OF (auxiliary contact), SD (alarm contact) | |||

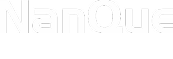

SIZE (UNIT: MM)

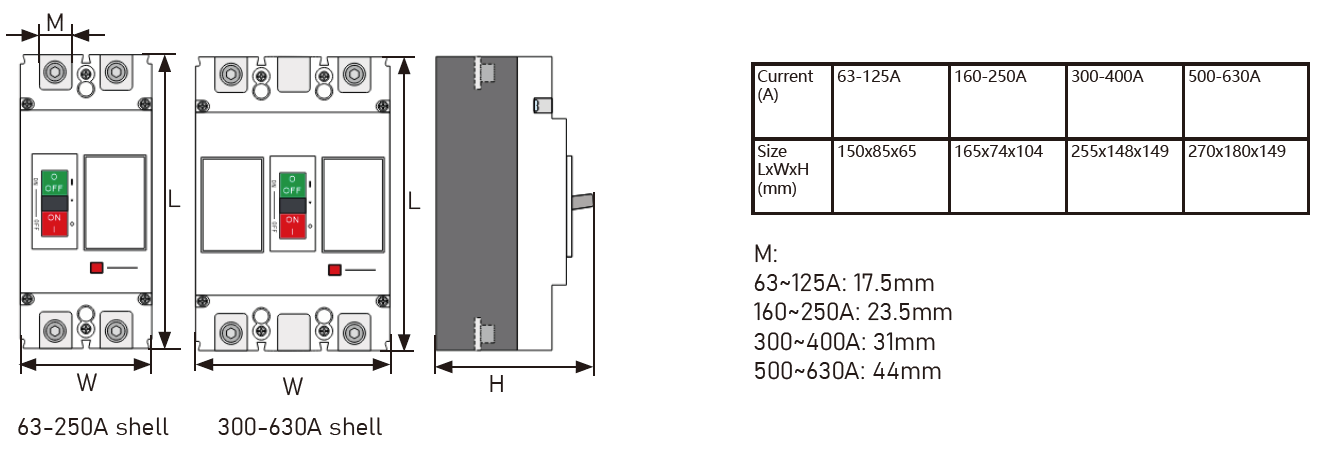

WIRING METHOD

CONNECTING CABLE

Model | Current | Recommended Cable (mm²) | Terminal Example | Maximum Wiring Capacity (mm²) |

NQCM1Z-125H | 63A | 16 | SC16-8 | 35 |

80A | 25 | SC25-8 | ||

100-125A | 35 | SC35-8 | ||

NQCM1Z-250H | 160A | 50 | SC50-8 | 70 |

200-250A | 70 | SC70-8 | ||

NQCM1Z-400H | 300A | 95 | SC95-10 | 120 |

350A | 120 | SC120-10 | ||

400A | 120 | SC120-10 | ||

NQCM1Z-630H | 500A | 150 | SC150-12 | 185 |

630A | 185 | SC185-12 |

Note: The examples are based solely on hard solid copper wires. For stranded flexible copper wires, as well as copper wires with different requirements for wire diameter and material under various national standards, calculations should be performed based on corresponding conversions. When necessary, copper bars should be used to connect multiple stranded flexible wires.

PRECAUTIONS AND WARNING

1, Ensure the circuit breaker is properly rated for the current, voltage, and frequency of the circuit it will control to prevent overloading and damage.

2, Always wear appropriate personal protective equipment (PPE) such as insulated gloves, safety glasses, and arc-flash clothing when operating or maintaining the circuit breaker.

3, Verify that the circuit is de-energized using a suitable voltage tester before performing any maintenance or inspection on the circuit breaker.

4, Avoid rapid or frequent switching of the circuit breaker, as this can cause excessive wear on internal components and reduce its lifespan.

5, Follow the manufacturer’s operating instructions and lockout/tagout procedures when isolating the circuit breaker to prevent accidental energization and ensure personal safety.